china supplier smart watch repair chips machine , welding machine BGA repairing WDS-660

Att: Isabel Fu

QQ: 1843067054

Skype: sales005-wisdomshow

Cell / WhatsApp / Wechat / Viber: +86 13266540971

Product Description

Can you show me details of WDS-660 ?

WDS-660 Youtube video :

https://www.youtube.com/watch?v=PqPkfruetuc

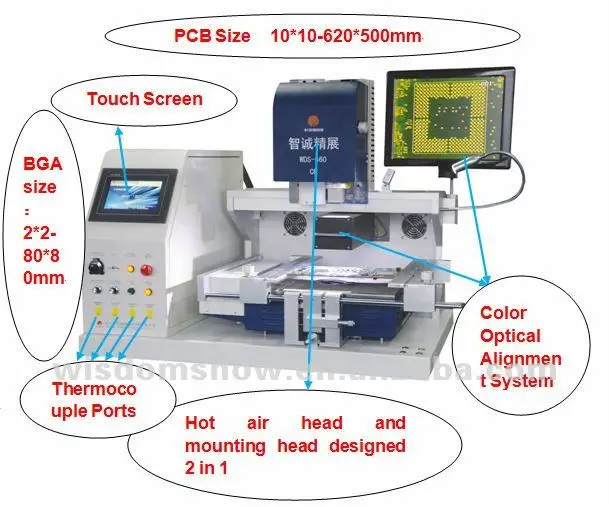

Specification of WDS-660 smart watch repair chips machine :

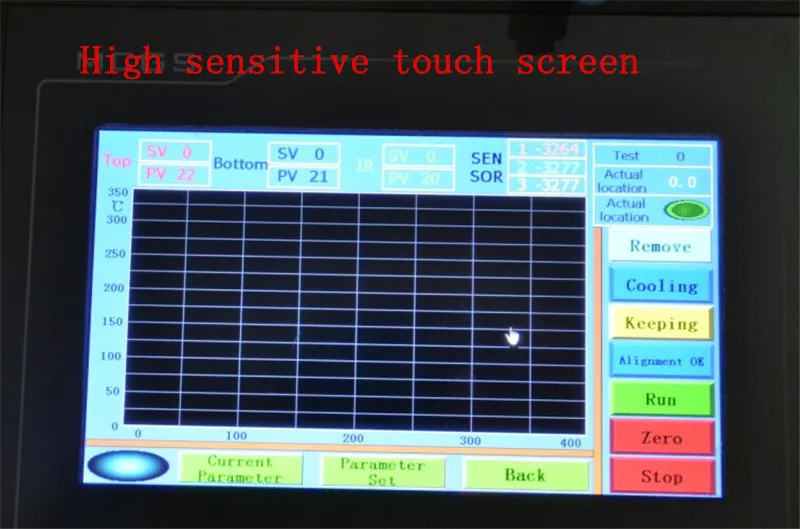

1.Touch screen interface and PLC controlling. display 3 temperature curves in any time.The temperature is controlled accurately between -1 degree and 1 degree. smart watch repair chips machine

2.6 segments controlling temperature, which could be controlled pre-heating, stillstand, heating, soldering 1, soldering 2 and cooling. The first-rate temperature controlling effectively ensure soldering effect.

3.The chips repair machine could save 1-100 phases temperature curves.You could analyze curve and change setting at touch screen.

4.There are 3 independent heating zones.The first and second heating zone could control the temperature in numerous phrases and the third heating zone pre-heating whole PCB so that achieve the best soldering effect.The temperature,time,slope,alarm are all displayed in the touch screen.

5.Accurately inspect temperature by high accurate K-type thermocouple with closed loop control.External temperature measurement interface detect temperature accurately.

6.Alarming after BGA was soldering and unsoldering.Circuit was interrupted automatically when the temperature is out of control which is double overtemperature protection function. smart watch repair chips machine

7.Adopt high power cross-flow wind to cool the PCB board quickly, preventing the PCB board from deformation to ensure soldering effect.

8.PCB board was located in"V"slot.The flexible and convenient universal fixture protect the PCB board.

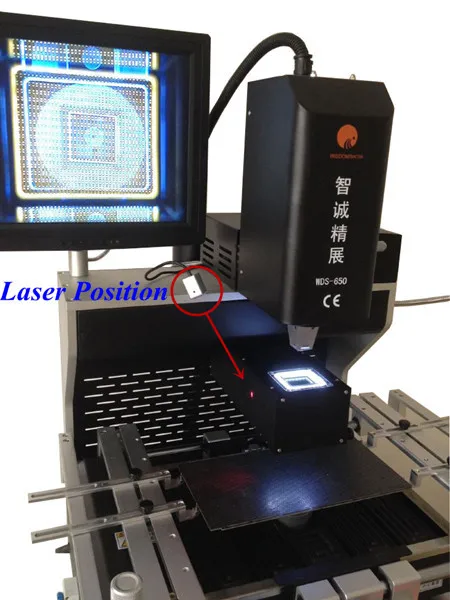

9.Touch screen control upside heating system and Optical alignment device system. Operation is convenient and flexible so that ensure alignment error within 0.01-0.02mm.

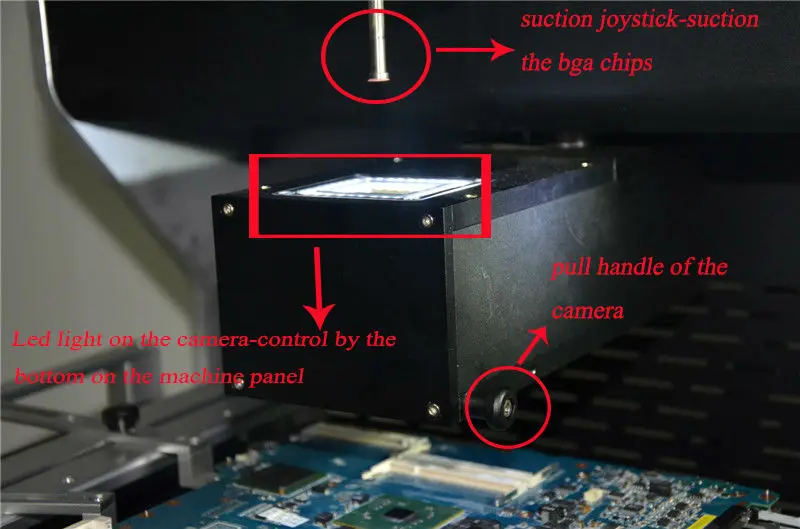

10.Hot air head and mounting head 2 in 1 design, stepping motor drivers,auto-solder and unsolder function. Equipped with various BGA sizes muzzles so that easy to replace. And the same time special requirements can be customized.

11.High precision optical vision system with optical image, fine adjustment and 15 inch color LCD monitor.

12.High automatic avoid manual mistake. Reworking lead free and double BGA board will be accurate. smart watch repair chips machine

Parameter of WDS-660 smart watch repair chips machine :

Total Power

|

Max 6600W

|

Upper Heating Power

|

1200W

|

Lower Heating Power

|

Second zone: 1200W, Third zone: IR 4200W

|

Power Supply

|

(Single Phase)AC 220V±10V 50Hz±3Hz 5.4 KVA

|

Machine Dimension

|

L1200*W800*H900mm

|

Positioning Way

|

V-shape card slot, PCB holder can be adjustable by X and Y axes

|

Temperature Controlling

|

K-type thermocouple closed loop control, independent temperature control

|

PCB Size(Max)

|

450*450mm

|

PCB Size (Min)

|

10*10mm

|

PCB Blowup Diploid

|

2-50X

|

Weight of machine

|

110Kg

|

Thermocouple Ports

|

4unit

|

Packaging & Shipping

What's Packaging & Shipping ?

1,Standard export wooden package for bga rework station.

2,Delivery in 2 workdays after payment confirm;

3,Shipping by TNT, UPS ,DHL, FEDEX(IE), Aramex, by air

or by sea.

or by sea.

4,Loading port: Shenzhen or Hongkong

Company Information

May i know about WISDOMSHOW company ?

Gift for you!More surprise!

Our Services

Engineers available to service machinery overseas

1.Professional factory manufacturing bga rework station,best production capability,best quality control,best service.

2.CE,Offer most competitive price.

3.100% QC inspection before shipment.

4.Speedy and high quality customer service and after-sale service possible.

5.Deliver goods to customer all over the world with speed and precision.

FAQ

1. How many days can we get the machines ? How many delivery ways can we chose?

The specific time according different shipping ways you chose.

By DHL,Fedex, UPS,etc (Door to Door Service), about 3-7 days to arrive

By Air to your airport (Door to Airport Service ), about 3-5 days to arrive.

By Sea to the seaport, about 30 days to arrive.

2. How about the package ? Is it safe during the delivery ?

All BGA rework machine is packed by standard strong wooden box with foam inside.

It can guarantee the safety of shipping.

3. Can you provide the warranty ? How about the after sales service ?

We have professional after sales team,supply 1 year warranty free for spare parts and whole life technical support. if any question,contact us in any time.

4. This machine is easy to operate? Do you provide the user manual to help me ?

Yes, we will provide the English user manual and can change the language as your requirement.The machine is humanized designed, do not worry,it is easy to operate.

5. What is the payment way ?

We accept the payment terms: Bank transfer, Wester Union, Moneygram, Paypal, Alibaba Pay,Aliexpress Pay,Credit Card etc.

Any other questions, Pls send INQUIRY , or CHAT with us, we will try our best to help you.

By DHL,Fedex, UPS,etc (Door to Door Service), about 3-7 days to arrive

By Air to your airport (Door to Airport Service ), about 3-5 days to arrive.

By Sea to the seaport, about 30 days to arrive.

2. How about the package ? Is it safe during the delivery ?

All BGA rework machine is packed by standard strong wooden box with foam inside.

It can guarantee the safety of shipping.

3. Can you provide the warranty ? How about the after sales service ?

We have professional after sales team,supply 1 year warranty free for spare parts and whole life technical support. if any question,contact us in any time.

4. This machine is easy to operate? Do you provide the user manual to help me ?

Yes, we will provide the English user manual and can change the language as your requirement.The machine is humanized designed, do not worry,it is easy to operate.

5. What is the payment way ?

We accept the payment terms: Bank transfer, Wester Union, Moneygram, Paypal, Alibaba Pay,Aliexpress Pay,Credit Card etc.

Any other questions, Pls send INQUIRY , or CHAT with us, we will try our best to help you.